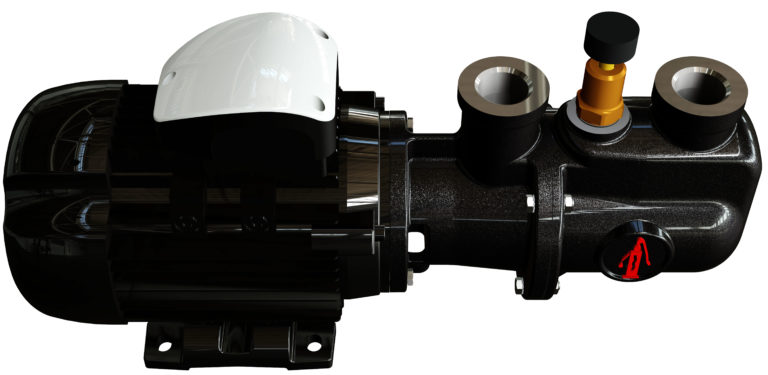

WOBBLE SERIES

As Naturem, if you are looking for a compact and versatile product, we can find a solution with Nova Rotors’ Wobble series.

We offer the opportunity to easily perform maintenance and reduce maintenance costs due to the small number of component parts. They can be used in a variety of industrial applications, as they can pump products that are viscous and have solids in the fluid or are slightly abrasive.

Perfect for those looking for a highly efficient, economical product, the Wobble series offers a unique cost/benefit advantage. They pump vibration-free even at high speeds and have almost no centrifugal effect. They are also suitable for use in the food industry as there are no dead zones inside the pump.

We are here to meet your needs with options of stainless steel, bronze, and cast iron body.

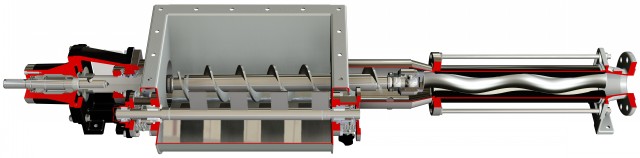

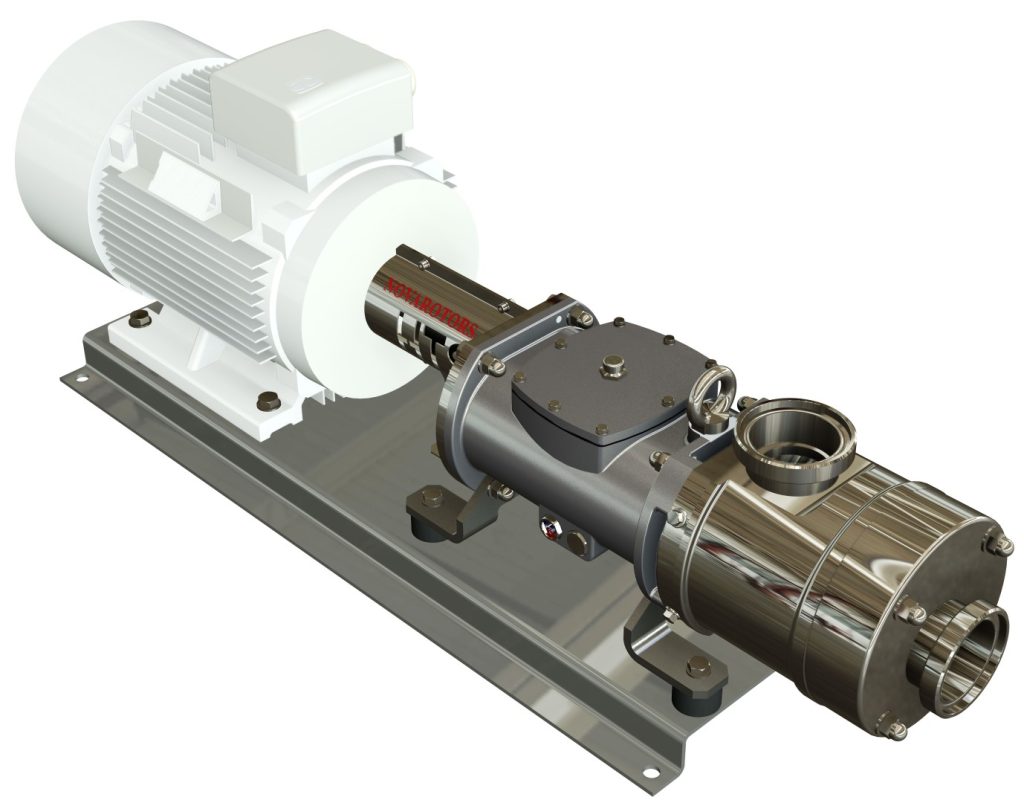

HTS (HYGIENIC TWIN SCREW) SERIES

HTS is the latest version of the hygienic twin screw technology. It is designed to achieve the maximum level of sanitation for the food and pharmaceutical market.

As Naturem, we attach importance to hygiene and stand by you with Nova Rotors hygienic positive displacement pumps in both product-based and project-based works in the food and chemical industry.

- Achieve high suction capacity with low NPSH values.

- Don’t be afraid to run dry as the rotors and pump housing are not in contact (with flushed seals).

- We are with you with our solutions for high viscosity products (up to 1,000,000 mPas)

- With the CIP process, it is possible to clean your pump before it stops.

You can contact us for solutions suitable for milk and dairy products, bakery products, beverages, cosmetics, chemicals, alcohol, and tomato paste production processes, as well as more detailed information.

We are at your side to meet your needs with stainless steel, bronze, cast iron body options.

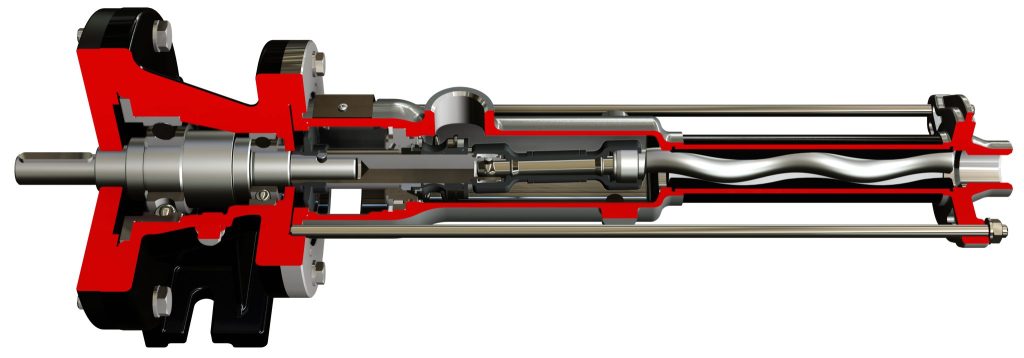

MONO PUMP SERIES

Mono pumps are equipment that ensure linear, smooth, stable, and turbulence-free transmission of fluid, according to their working principle. By transmitting the torque it receives from the motor to the shaft, it enables the transmission of the fluid with the help of the rotor, which is the rotating part inside the pump. These pumps are designed to be suitable for low and high viscosity, particle-containing or abrasive fluids. Their preference is due to their non-vibration and quiet operation. Mono pumps can be used even under the most challenging conditions to preserve the characteristics of the product passing through the pump.

If you want to adjust the amount of your flow (flow rate) according to your process, Naturem is at your side with frequency converter compatible pumps as well as the installation of automation.

There are some points to be considered when operating in mono pumps;

- Performing pump maintenance at regular intervals

- To prevent the product from freezing in the pump and for a healthy pump, it is absolutely necessary to clean the surfaces of the pump in contact with the fluid before each stop and to stop in that way.

- Do not run dry because it is not suitable for dry operation.